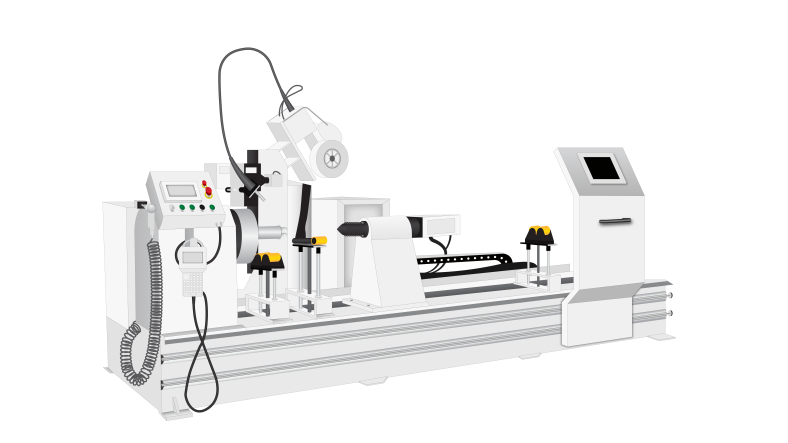

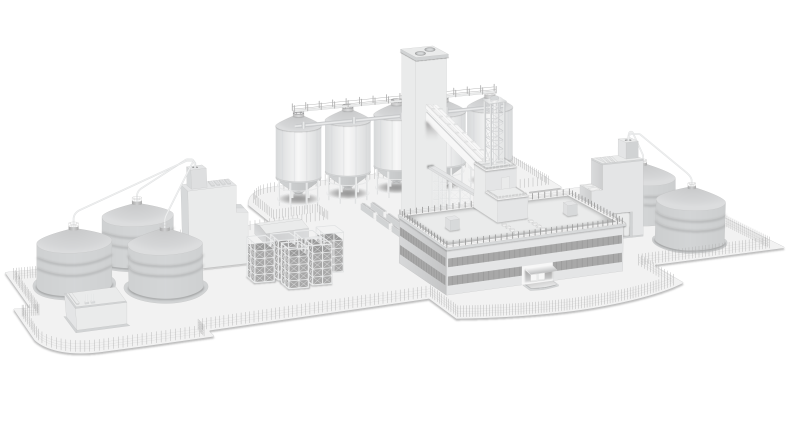

Welding Solution For Automotive Industry

The leading edge technology in welding application for automotive industry has become essential today making new combination of Auto body Parts. Innovative welding technique enables automotive manufacturer focus on welding process to joint lighter yet strong and fuel efficient vehicle parts employing lightweight materials. Welding solution of LUBI in automotive industry offers manufacturers flexible and sustainable welding development with the help of advance automation products and high precision mechanical parts for complex corrosive environments.