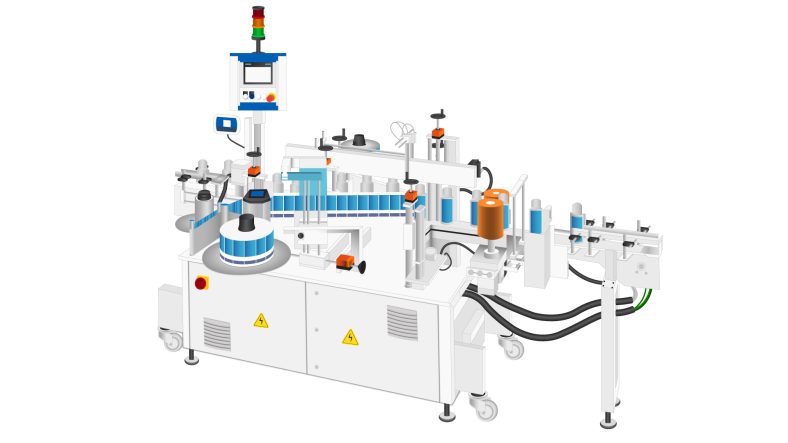

The Delta Compact Modular Mid-range PLC AS Series is a high performance multi-purpose controller designed for all kinds of automated equipment. It features Delta's self-developed 32-bit SoC CPUs for enhanced execution speed (40 k steps/ms) and supports up to 32 extension modules or up to 1,024 inputs/outputs. The AS series provides accurate positioning control for up to 8 axes via the CANopen motion network and max. 6 axes via pulse control (200 kHz). It is widely used in diverse automated equipment such as electronics manufacturing, labeling, food packaging, and textile machines.

● New 32-bit SoC (System on Chip) CPU to enhance execution speed(40 k steps/ms)

● Positioning control function for up to 8-axis motion control via CANopen / 6-axis 200 kHz pulse control

● Robust non-backplane design and patented DIN rail clips for vertical module installation and replacement

●ISPSoft editing software for programming, hardware configuration, network communication, system diagnostics, and positioning planning

● New 32-bit SoC (System on Chip) CPU

● Max. I/O: 1,024

● Program capacity: AS300 series 128k steps, AS200 series 64k steps

● Data registers: 60k words

● Extension modules: max. 32 (analog modules: max.16 / communication modules: max. 4)

● Execution speed: up to 40 k steps/ms

- Basic instruction (LD): 25 ns

- Application instruction (MOV): 0.15 μs

● The abundant selection of DIO modules, AIO modules, temperature modules, load cell modules, and function cards.