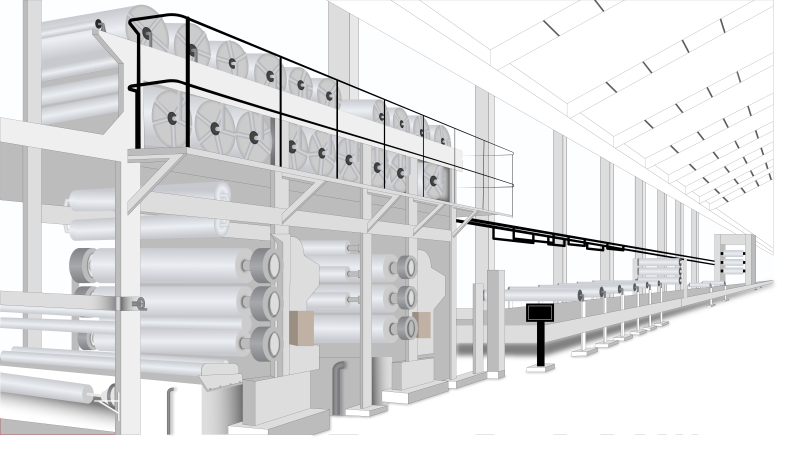

Mercerizer Plant

Mercerizer Plant in the Textile industry lead to improve the property of the fabric like luster, tensile strength, absorption of dyes, coverage of dead cotton, and dimensional stability. The many benefits that arise from normal mercerizing are, nevertheless, largely surface effects, particularly on woven fabrics. With enhanced product portfolio LUBI provides controlling of fabric throughout the plant with VFD, running in torque control mode for finished product passing through various processes controlled & monitored by PLC and HMI.