- Home

- Industries

- Warehouse and Logistics

Warehouse and Logistics

New logistic revolutions through Automation

Multiple technology advancements pushed leading retailers to have Warehouse and Logistics more responsive, resilient and reliable to serve B2B or B2C business which emphasis on Warehouse Automation. Logistics managers strive to maintain stock accuracy, picking optimization, quick delivery of products & reduced labor costs to increase productivity and quality control for packing and shipping of inventory items.

LUBI delivers Age of Technology

✔ LUBI helps warehouse industry to prevent picking of wrong part by providing picking sensors, which can disrupt an inventory control system, it supplies industrial Barcode readers to keep inward and outward data emphasizing on quick delivery of product.

✔ LUBI provides comprehensive solution in Robotics with precise Gear Reducer and AC Servo motors to pick and place of products for quality control and reduces labor forces, while enables AGV solution for scalable inventory and reduce supply chain issues.

✔ The Software solution from LUBI enables to incorporate protocol gateways with IPC and SCADA to manage everyday inventory data in a structured manner that encourages accountability.

Applications

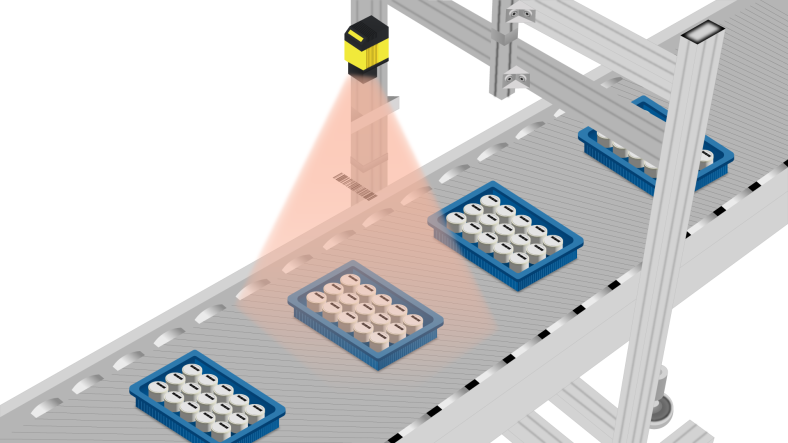

Image Based Barcode Scanning

Image based Barcode Readers are rapidly upgrading manual process and old traditional laser scanner in many of industries like Food and Beverages, Logistics and Pharmaceutical. The Series comes with fixed mounting type to solve complex, high throughput in logistics applications offers flexibility to manufactures think less about setup in their machine design. LUBI delivers image based barcode readers to read multiple challenging 1D and 2D codes in varied locations on production line, ideal for automotive and logistics component traceability.

Learn More