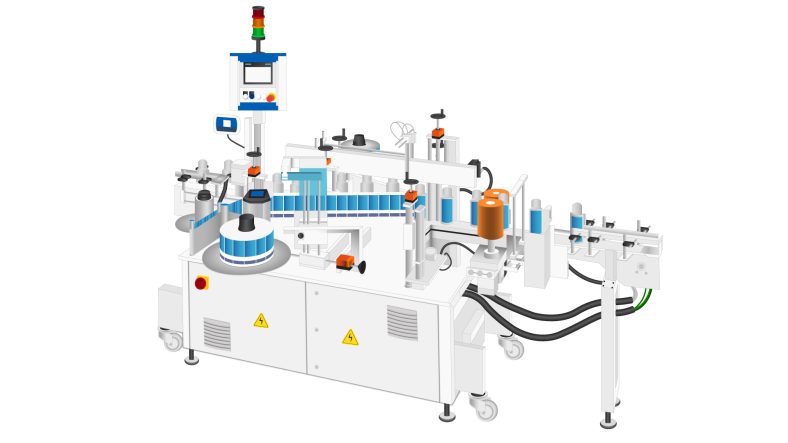

Delta's MS300 series are the new generation high performance and standard compact vector control drives that inherit Delta’s superior drive technology—all in a compact drive that has been reduced 40% in size.

A variety of essential functions are built-in as standard, including: PLC capacity for simple programming needs, communication slots for various communication cards, and a USB port to make data uploads and downloads fast and easy.

This saves the need for additional hardware, while providing more installation space for the power cabinet.

Other key features include: Support for both IM and PM motor control for application flexibility, an STO function to ensure worry-free operation while protecting facilities from damage, and a simplified wiring process with a new screwless wiring design of terminal blocks for quick installation.

Saving space, reducing setup and wiring time, and providing high efficiency and a highly stable system, the MS300 micro drives are your key to improving market competitiveness and ensuring success.

● Supports Open-loop control of IM and PM motors

● Output frequency:

● Standard models: 0 to 599 HzHigh speed models: 0 to 1500 Hz (V/f Control)

● Dual rating design:120% for 60 seconds for Normal Duty (ND)150% for 60 seconds for Heavy Duty (HD)

● Built-in PLC program with 2K steps capacity

● Built-in brake choppers for the entire series

● Removable 5-digit LED keypad for remote operation

● Safety standard compliance: Safe Torque Off (SIL2/PLd)

● Multi-motor Control, built-in four IM motor control parameters

● Optional built-in Class A (C2) standard EMC filter for 1-phase 230V, 3-phase 460V models

● One high-speed pulse input terminal MI7 built-in with maximum speed up to 33kHz

● One high-speed pulse output terminal DFM built-in with maximum speed up to 33kHz

● New PCB coating for circuit (IEC 60721-3-3 class 3C2) and thermal design suitable for harsh environment applications

● Built-in RS-485 (Modbus) and various communication card options: CANopen, PROFIBUS DP, DeviceNet, MODBUS TCP, EtherNet/IP, EtherCAT

Power Range

230V/1 ~ Phase 0.25HP ~ 3HP

460V/3 ~ Phase 0.5HP ~ 30HP