- Home

- All Partners

- Cognex

- Deep Learning

- VisionPro Deep Learning

- Blue Locate Tool

Blue Locate Tool

- Home

- All Partners

- Cognex

- Deep Learning

- VisionPro Deep Learning

- Blue Locate Tool

Blue Locate Tool

VisionPro® Deep Learning is the best-in-class deep learning-based image analysis software designed for factory automation. Its field-tested algorithms are optimized specifically for machine vision, with a graphical user interface that simplifies neural network training without compromising performance. VisionPro Deep Learning solves complex applications that are too challenging for traditional machine vision, while providing a consistency and speed that aren’t possible with human inspection. When combined with VisionPro’s rule-based vision libraries, automation engineers can easily choose the best the tool for the task at hand

VisionPro Deep Learning’s graphical training interface simplifies the task of collecting images, training the neural network, and testing it on a variety of image sets. The unique tool-chaining capability lets users break down their problem into smaller steps, making it easier to optimize and requiring fewer training images

Users can take advantage of the extensive selection of traditional machine vision tools alongside innovative deep learning tools. VisionPro Deep Learning provides access to deep learning toolsets through programmatic integration, as well as through the Cognex Designer™ graphical development interface. From low-level machine integration to deploying an application-specific HMI using Cognex Designer, VisionPro Deep Learning provides flexibility in how you develop and integrate the vision inspection to your production environmen

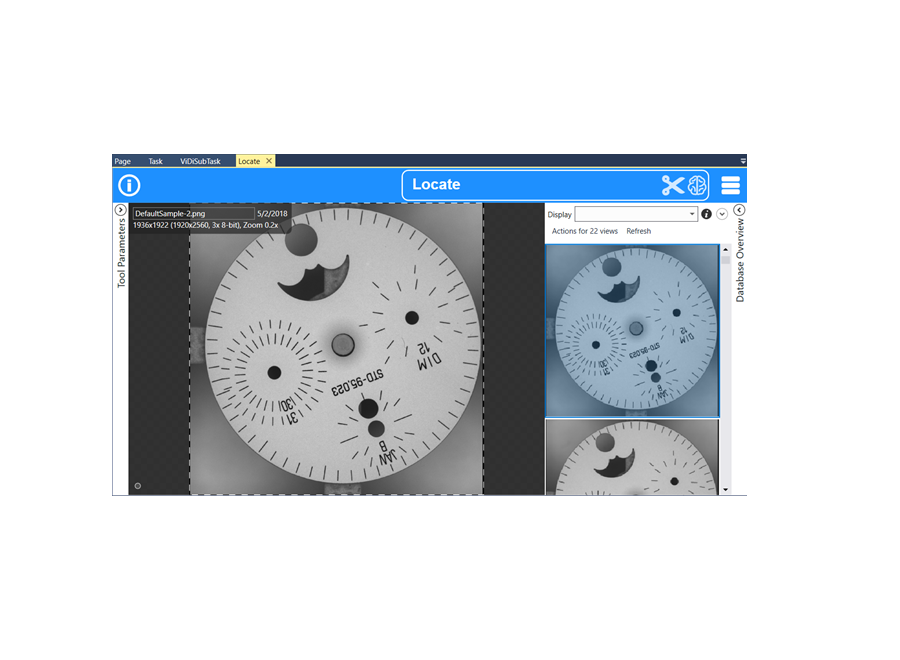

● The Blue Locate tool is deep learning image analysis software used in manufacturing for finding complex features and objects within a field of view. Blue Locate detects features on noisy backgrounds, in poorly lit environments, on low contrast parts, and even parts that flex or change shape. It locates parts despite variations in perspective, orientation, luminance, glare and color by learning from the samples provided by the user

● Blue Locate also offers a reliable automated solution for assembly verification. A single tool can be trained to find a variety of components, even if they appear at different angles or vary in size, to create an extensive component library. By creating layouts based on the product being inspected, the tool can check multiple feature locations and components types simultaneously, while adjusting to varying layouts