Sit amet, consectetur adipiscing elit. Ut elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

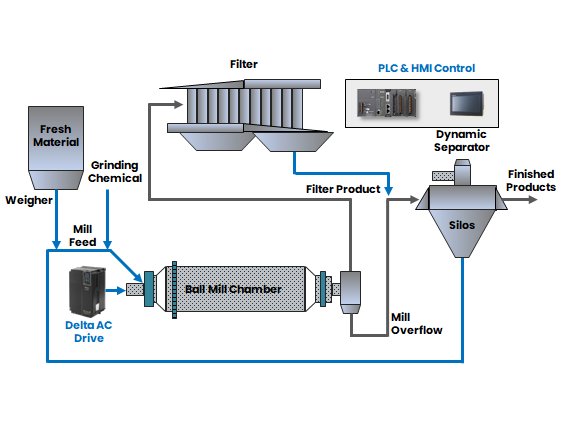

Milling of Lime & Stone is one of the most energy intensive and cost expensive areas of Ceramic Industry. Every modern milling is striving to operate its grinding process at its best operating point, minimising energy consumption, maximising output and all while keeping the operation more stable. Optimized control process enables to achieve Automation goals to pursue this delicate balancing act of these complex objectives.

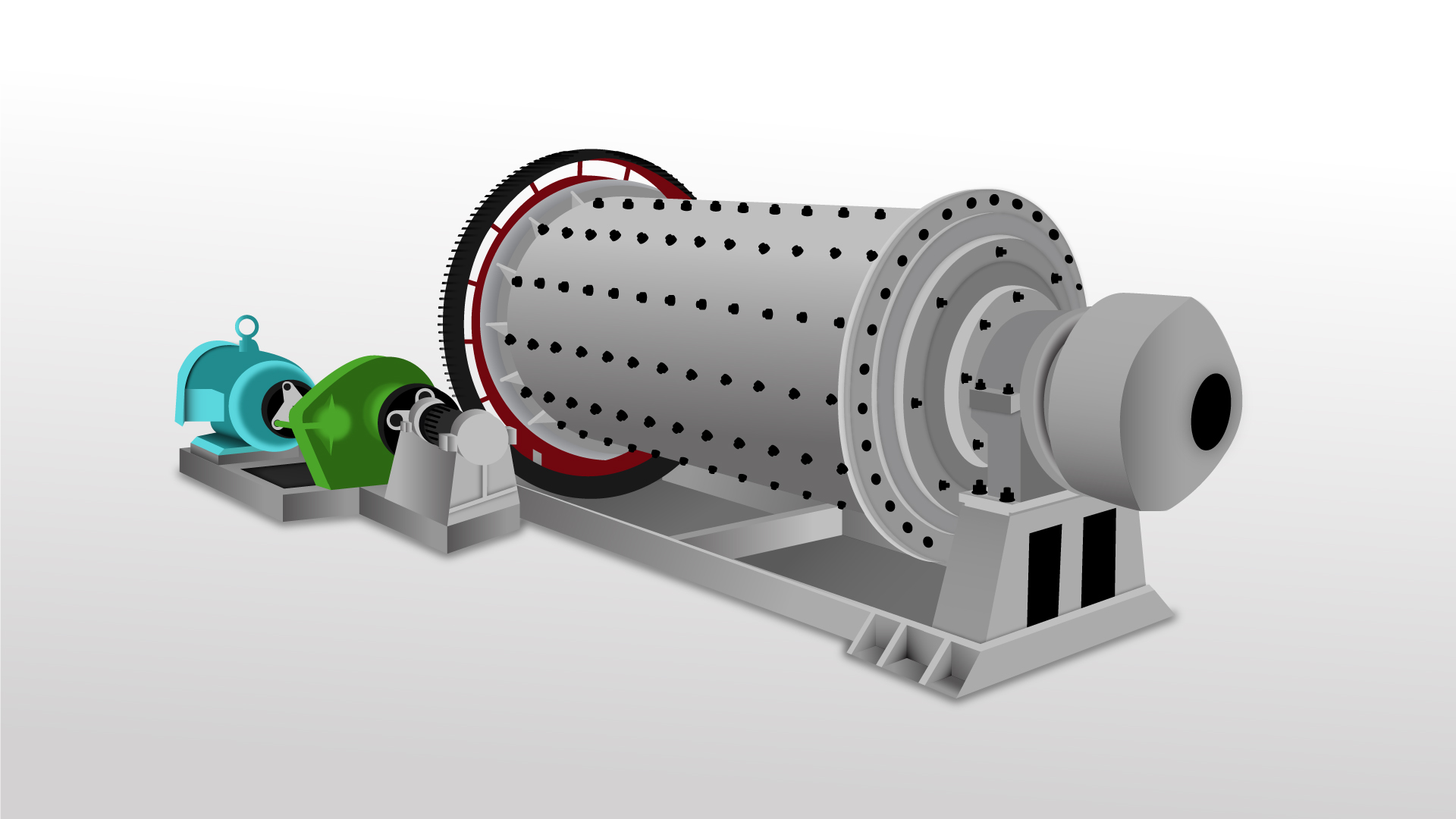

Ball Mills are widely used for comminuting process in Mining and Ceramic Industry. The Comminuting in the ball mill take place by impact, friction and abrasion between rocks and metal ball inside results in more energy consumption and reduced production rate.To cope up with these challenges required to have determined control process averting traditional grinding methods.With aid of optimized control system, LUBI caters solution with reduced energy consumption and enhanced production to their customers.

Ball mill plant carries unified process starting from weighing the raw material to travel from Feeder silo to conveyor. Steel Balls are charged in the Horizontal ball mill to be ground and rotated. Raw ingredient then filled into ball mill and then collision starts of Steel balls and ore to hit and crush results making final output of products to be used in Ceramic industry. Main concern about grinding is to ensure stability and many equipment parameters need to control like rotation speed of scattered machine, form of material, quantity of feeding and dust collecting equipment.

The Process modernization involves integration of control system which aid to reduce energy consumption and raised output efficiency. Lubi adapts PLC control system collaborated with Variable frequency drive to make close loop control considering feedback of heavy load consumed in operation accountable to the criteria of energy efficiency and reliability of the drive which makes system potent to save cost and performance enhanced operation.

Evaluation of the Drive Modernization

✔ Energy Saving up to 5~10% can be expected

✔ Soft Start Operation lowering current consumption

✔ Auto Cutoff at desired pressure feedback from Sensor

Potent Performance of System

✔ Higher Input Power Factor

✔ Increase in production up to 5%

✔ Improved process stability through Control System

Hassle free operation and Troubleshooting

✔ Motor load protection with Automatic Torque Boost

✔ Minimize downtime, equipment wear and maintenance costs

✔ Reduce Maintenance Cost