Sit amet, consectetur adipiscing elit. Ut elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

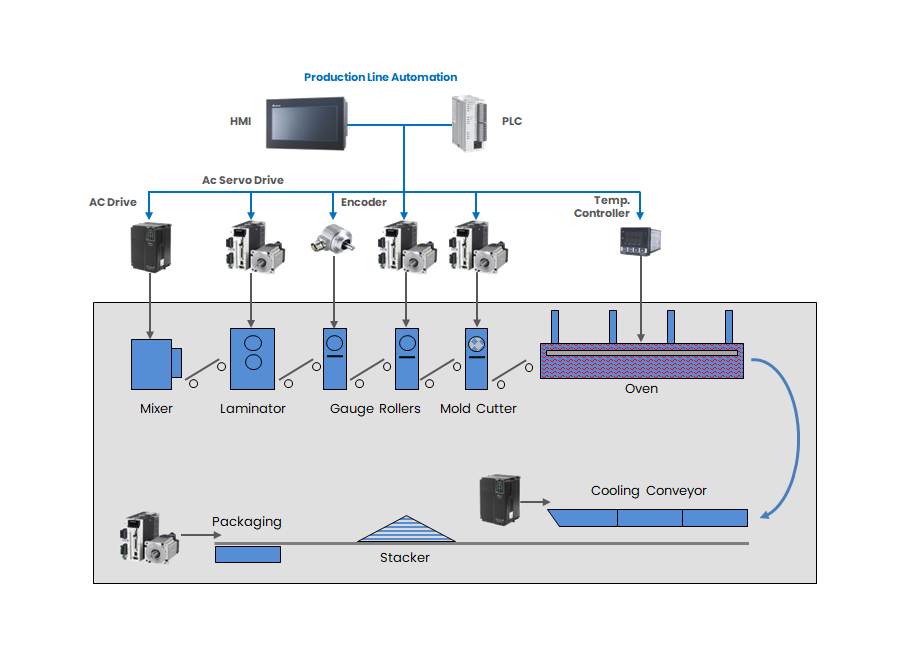

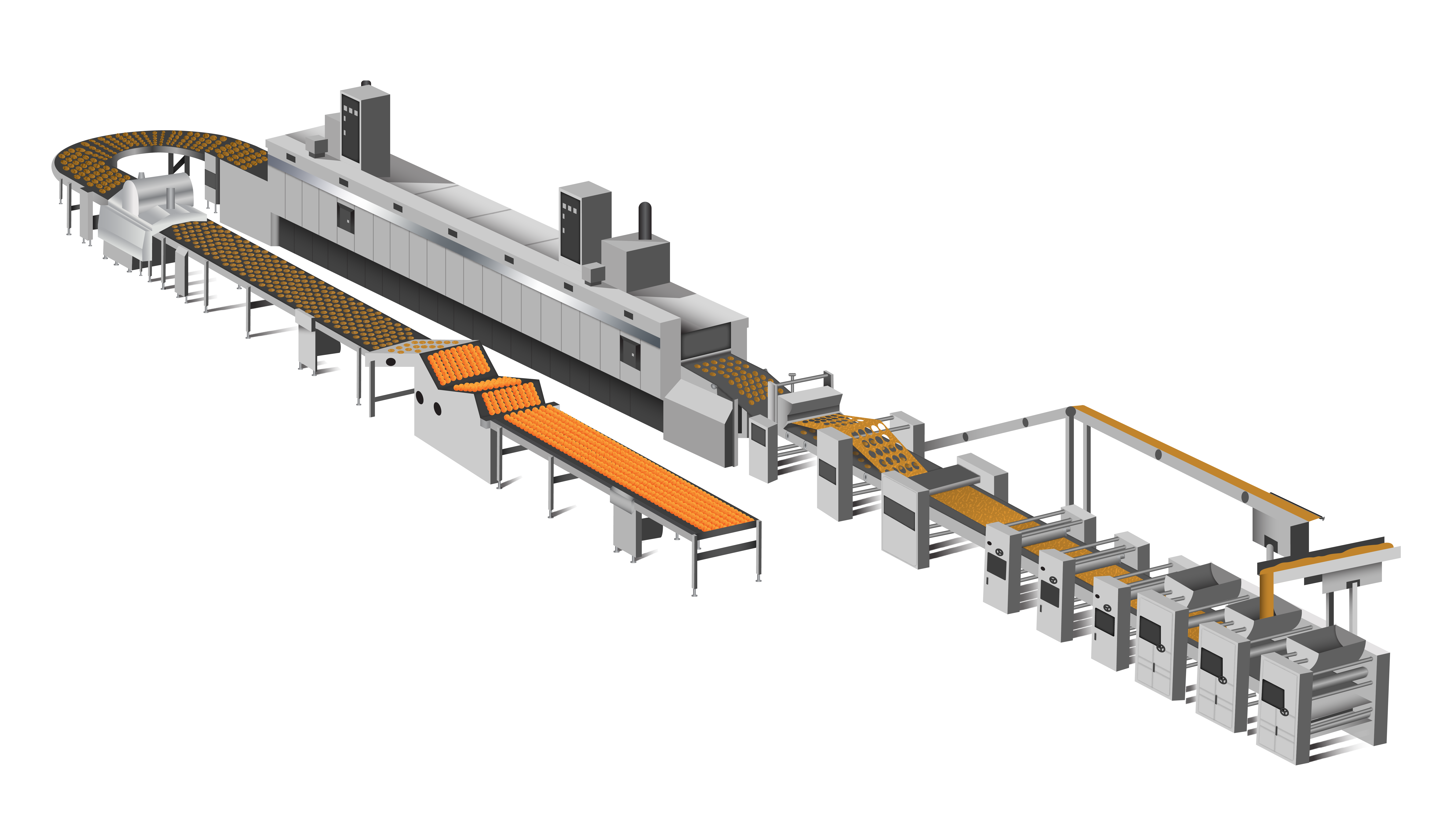

The Biscuit Plant produces biscuits as per defined synchronisation with rest of the unit. Automatic system of biscuit plant includes relative process operated and managed by automation solution with precise cycle time to make perfect product with mixing of ingredients, rolling with desired thickness, shaping of biscuits and loading on conveyor belt to send in oven for baking and final packaging following cooling process. Automatic plant helps producers to maintain the integrity of biscuit in terms of quality and packaging through rationalized process.

Automatic biscuit plant aims limiting human contact with the product to meet hygienic demand. Process carries mixing of all the ingredients take place in automatic mixtures like flour, butter, milk, sugar, eggs and baking soda can be done through single or multiple stages depending upon the type of biscuit to be manufactured.

The dough is placed on hopper connected to the conveyor and the journey of manufacturing cracker starts. The soft dough is first made flat (PGR) to make sheets (By Laminator) out of the dough. The dough sheets then compressed under series of gauging rollers. The Gauged sheet then fed into the rotary cutter. The rotary cutter, a rotating roller with cups attached around it, is used then to get the desired shaped biscuits ready to bake. The biscuits from the rotary cutting are supplied to the oven for baking it in desired temperature for desired durations. The hot biscuits need to be cooled before it can be tested or packaged. The cooling is done over the conveyor itself. After the cooling, samples of the cookies are tested to ensure quality and tests. After preparation of final product sent for packaging machines and the product becomes ready to serve their consumers in the retail market after Product evaluation of Quality and Packaging.

Broad Customer base carried by enhanced service support, LUBI offers plant solution incorporating discrete process utilised with AC Servo motors to make precise thickness of dough sheet and shaping of mould roller controlled by PLC while intelligent sensor solution to maintain desired temperature in oven for biscuit baking and features operational mimic in HMI to monitor process flow of the plant with essential information.

Ease of Line synchronization & Full Line Recipe Control

✔ Precise, automatic, and synchronized control of dough sheet length, conveyor speed, and number of laminations

✔ Recipe control for configurable sheet lengths and number of laminations

Advance Servo technology to enhance productivity

✔ High Torque Servo for Laminator section

✔ Independent Speed tuning even in AUTO operation

✔ Gauging selection by Servo / Encoder Feedback Setting for Accuracy

Optimizes output and efficiency to improve products and process.

✔ Production capacity more than 400Kg/H

✔ Automatic temperature control system

✔ Protection from overvoltage & fault indications current situations Ease of operation indexed from the touchscreen control interface