Sit amet, consectetur adipiscing elit. Ut elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

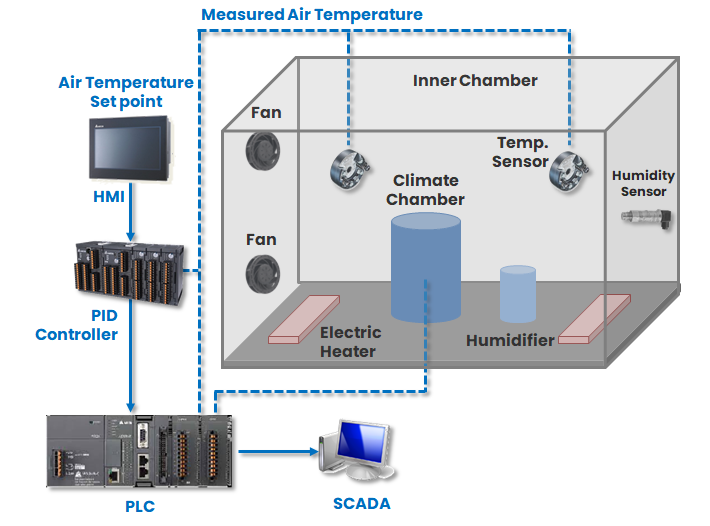

Control of the test chambers allows technician for various testing conditions to be set and monitored from their desktop computers or laptops. Views of set points, temperature, humidity and discrete parameters with preset graphics once can be customized to the special condition. Customers expect solutions that can provide accurate control of various equipment conjunctive to experiment box of desperate size in various industry segments.

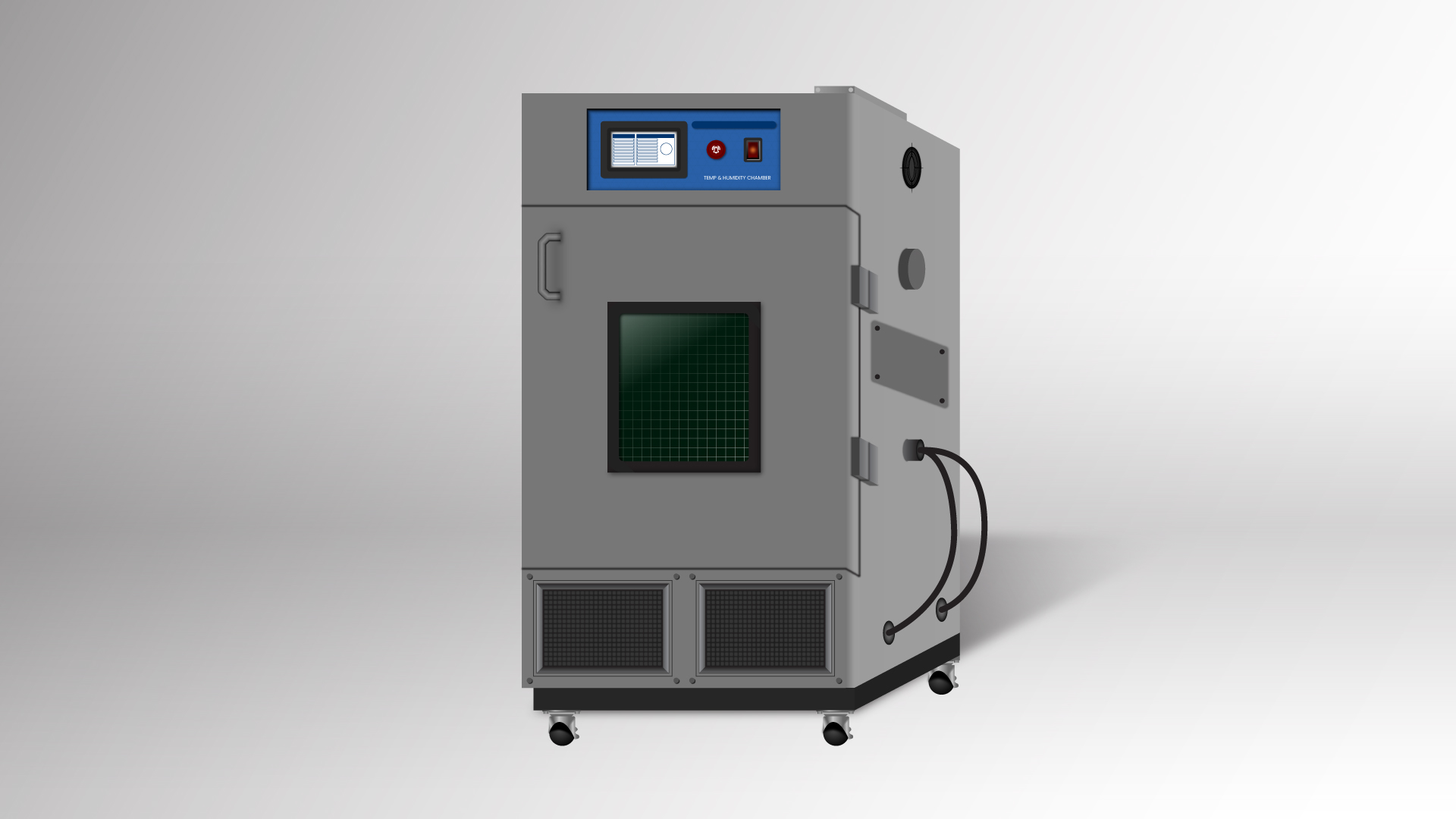

Climate test chambers comes in a variety of sizes, from a small box that fits on the bench top to a room-sized chamber for large objects or for testing large batches of product simultaneously. Temperature ranges from -90C to 200C and relative humidity ranges between 10% to 98%.

Compressors are used to control the temperature with air heaters while boiler tank / boiler heaters are used to control humidity. Compressors are continuously working and Air heaters are controlled through PID to maintain the desired the temperature. Now-a-days new control phenomena are used in which compressors are kept on ON-OFF mode to utilize power efficiently.

Solution from LUBI provides PLC and PID controllers to keep monitoring and storing the actual reading from sensors and controlling compressors, air heaters and boiler heaters. Also it monitors other standby sensors and compares each value with master control sensor to store alarms.

PLC takes records of actual parameters periodically and stores in memory through Ethernet gateways connected with SCADA in IPC, which can be useful for audit later in the form of Electronic Batch Report to customer for non-editable report of product analysis.

Operators can easily identify and diagnosis the alarms & actual process data through HMI and can take printout of required data for various production batch reports.

Designed for Indirect Experiments

✔ Software-based simulation in Real Environmental conditions

✔ Fast execution of programmed temperature changes

✔ Data integrity with cloud based solution

✔ HMI generates non-editable Electronic batch report

Accurate and Precise Control

✔ Precise Temperature, Humidity and Speed Control through PLC

✔ Gain achieved with discrete PID Sets

✔ Specifically Tuned PID for Fast Response

Safety Features for Improved Performance

✔ Over Temperature/Current Protection

✔ Refrigerant High Pressure Protection

✔ Humidifier Dry Combustion