In the fast-paced world of manufacturing, time is of the essence, and any delays or inefficiencies can have a significant impact on your bottom line. When it comes to pallet welding, efficiency is everything. That’s where the Delta Welding Robot comes in – the ultimate solution for pallet welding.

This cutting-edge technology is designed to maximize your efficiency and streamline your production process, allowing you to meet your deadlines and deliver high-quality products consistently. With its advanced features and innovative design, LUBI has provided comprehensive solution of Delta Welding Robot for any manufacturing operation looking to take their pallet welding to the next level. In this article, we’ll explore the benefits of using the Delta Welding Robot and how it can help you achieve your business goals. So, let’s dive in and discover how this impressive technology can transform your manufacturing process for the better.

The Need for Efficiency in Pallet Welding

Pallets are an essential component of the logistics industry. They are used to transport goods and materials from one place to another, and their durability and stability are critical to ensuring that the cargo arrives safely. Pallets are most commonly made from wood, and welding is a crucial step in their manufacture. Welding ensures that the pallets are strong and can withstand the rigors of transportation.

However, welding can be a time-consuming and labour-intensive process. Traditional welding methods require skilled workers to manually weld the pallets, which can take a significant amount of time, especially when large quantities of pallets need to be produced. This process is not only time-consuming but also prone to human error. Any mistakes made during the welding process can compromise the integrity of the pallets, resulting in increased costs and potential safety hazards.

Therefore, it’s essential to find a more efficient solution to pallet welding. The Delta Welding Robot offers the perfect solution to this problem. With its advanced technology and innovative design, the Delta Welding Robot can maximize efficiency and reduce the time and labor required for pallet welding.

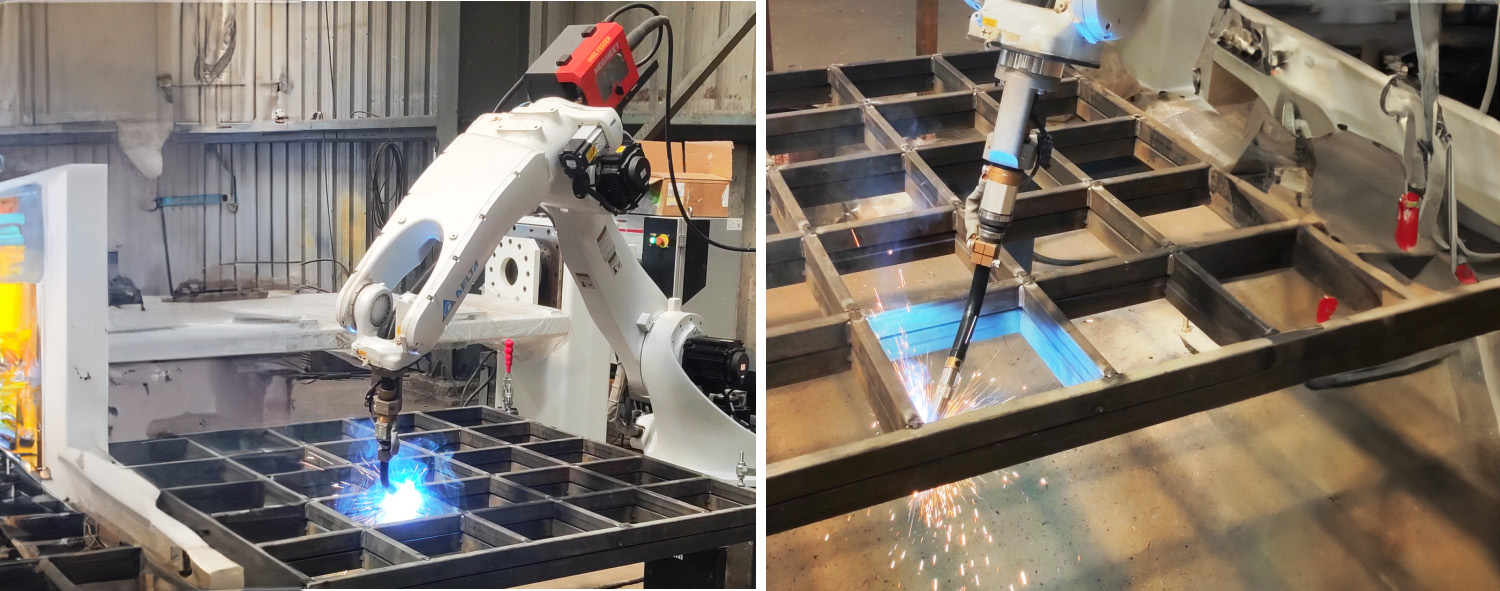

Introducing the Delta Welding Robot

The Delta Welding Robot is a cutting-edge technology designed specifically for pallet welding. It is a fully automated system that can weld pallets quickly and efficiently, reducing the need for manual labor and increasing productivity.

The Delta Welding Robot uses a three-axis system that can weld multiple pallets simultaneously, significantly reducing the time required for pallet welding. This system is also highly accurate, ensuring that each weld is of high quality and meets the necessary standards.

The Delta Welding Robot also comes with a user-friendly interface that makes it easy to operate. Its intuitive design makes it easy for operators to set up the system and monitor the welding process, ensuring that everything runs smoothly.

How the Delta Welding Robot Maximizes Efficiency

The Delta Welding Robot is designed to maximize efficiency and reduce the time and labor required for pallet welding. Here are some of the ways the Delta Welding Robot achieves this:

Automated Welding Process

The Delta Welding Robot is a fully automated system, which means that it can weld pallets without the need for manual labor. This significantly reduces the time required for pallet welding and increases productivity.

Multi-Axis System

The Delta Welding Robot’s three-axis system allows it to weld multiple pallets simultaneously, significantly reducing the time required for pallet welding.

High-Quality Welds

The Delta Welding Robot’s advanced technology and innovative design ensure that each weld is of high quality and meets the necessary standards. This reduces the need for rework and increases the efficiency of the pallet welding process.

User-Friendly Interface

The Delta Welding Robot’s user-friendly interface makes it easy to operate. This intuitive design makes it easy for operators to set up the system and monitor the welding process, ensuring that everything runs smoothly.

Features and Benefits of the Delta Welding Robot

The Delta Welding Robot comes with several features and benefits that make it the ultimate solution for pallet welding. Here are some of them:

High-Speed Welding

The Delta Welding Robot’s advanced technology allows it to weld pallets quickly and efficiently, significantly reducing the time required for pallet welding.

Reduced Labor Costs

The Delta Welding Robot’s fully automated system reduces the need for manual labor, which can significantly reduce labor costs, making it a cost-effective solution for pallet welding.

Increased Productivity

The Delta Welding Robot’s advanced technology and innovative design increase productivity by reducing the time required for pallet welding.

Improved Safety

The Delta Welding Robot’s fully automated system reduces the risk of accidents and injuries associated with manual welding.

Cost and ROI Considerations of the Delta Welding Robot

While the Delta Welding Robot offers several benefits, it’s essential to consider the cost and ROI before investing in the technology. The cost of the Delta Welding Robot can vary depending on the model and features you choose. However, the investment in the Delta Welding Robot can pay off in the long run through increased productivity, reduced labor costs, and improved quality.

It’s essential to consider the ROI of the Delta Welding Robot before investing in the technology. The ROI can vary depending on several factors, such as the number of pallets produced, labor costs, and the cost of the Delta Welding Robot. However, a well-planned implementation of the Delta Welding Robot can result in a positive ROI within a short period.

Case Studies of Successful Implementations of the Delta Welding Robot

LUBI enables several manufacturing operations to have successfully implemented the Delta Welding Robot in their pallet welding process. Here are some of the case studies:

Case Study 1: XYZ Manufacturing

XYZ Manufacturing implemented the Delta Welding Robot in their pallet welding process and saw a significant increase in productivity. The Delta Welding Robot allowed them to weld pallets quickly and efficiently, reducing the time required for pallet welding by 50%. This resulted in a positive ROI within six months of implementation.

Case Study 2: ABC Manufacturing

ABC Manufacturing implemented the Delta Welding Robot in their pallet welding process and saw a significant reduction in labor costs. The Delta Welding Robot’s fully automated system reduced the need for manual labor, resulting in a 40% reduction in labor costs. This resulted in a positive ROI within nine months of implementation.

Comparing the Delta Welding Robot to Other Pallet Welding Solutions

While the Delta Welding Robot is the ultimate solution for pallet welding, it’s essential to compare it to other pallet welding solutions to understand its advantages. Traditional welding methods require skilled workers to manually weld the pallets, which can be time-consuming and labour-intensive. Other automated pallet welding solutions may not be as efficient or accurate as the Delta Welding Robot.

Choosing the Right Delta Welding Robot Model for Your Business

Choosing the right Delta Welding Robot model for your business is essential to maximize efficiency and productivity. The Delta Welding Robot comes in several models, each with different features and capabilities. It’s crucial to choose the model that best fits your business needs and goals.

Conclusion: Why the Delta Welding Robot is the Ultimate Solution for Pallet Welding

The Delta Welding Robot is the ultimate solution from LUBI for pallet welding. Its advanced technology and innovative design maximize efficiency and productivity, reduce labor costs, and improve the quality of pallet welding. LUBI’s successful implementations of the Delta Welding Robot have resulted in positive ROI within a short period, making it a cost-effective solution for pallet welding. Choosing the right Delta Welding Robot model for your business can help you achieve your goals and take your manufacturing process to the next level.