Metal fabrication is a critical aspect of manufacturing involving various complex processes requiring high precision and accuracy. In this domain, Motion Components technology plays an essential role. As the foundation of all operations, Motion Components guarantee the flawless execution of metal fabrication tasks such as cutting, bending, forming, and assembly.

What are Motion Control Components?

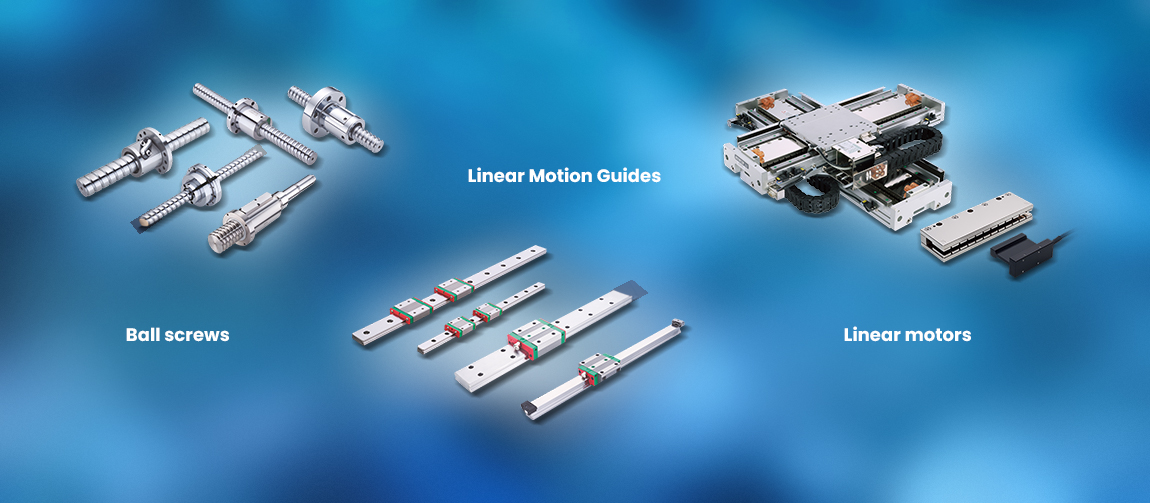

Motion Control Components refer to devices and systems utilized in industrial and manufacturing settings to regulate the movement of machinery and components with precision, accuracy, and efficiency. These products encompass various components and technologies designed to manage and direct motion, such as linear motors, ball screws, and linear guides.

Components of Motion Control

Linear motion guides also called linear bearings or slides, allow smooth and precise motion in machines. They reduce friction and enable controlled movement, which is important for accuracy in assembly lines, robotics, and material handling equipment.

Ball screws convert rotational motion into linear motion using a threaded shaft and a nut with ball bearings. They're accurate, efficient, and low friction, making them ideal for industrial machines and automation systems.

Linear motors offer direct linear motion without the need for mechanical components like belts or pulleys. They're perfect for high-speed and high-precision movement, making them ideal for CNC machines and semiconductor manufacturing.

Motion Components Solutions in Metal Fabrication

The use of Motion Components solutions improves the efficiency, accuracy, and quality of metal fabrication processes. Let's explore their various applications:

Cutting and Sawing

Bending and Forming

Assembly

Linear Motors in Automation

The Power of Linear Motors in Metal Fabrication

Linear motors have emerged as a game-changer in the metal fabrication industry. They provide swift and easily controllable movements, offering unparalleled stability and precision. These linear motors operate with exceptional accuracy and stability, completing intricate manufacturing processes swiftly and with remarkable detail.

The Advantages of LUBI's Linear Motors:

♢ Enhanced Precision: Linear motors operate with minimal vibration, significantly improving the accuracy of cutting tools. This stability ensures smooth movements of both workpieces and tools, ensuring optimal load and speed for precise fabrication.

♢ Reduced Maintenance: Compared to traditional motors, linear motors require less maintenance and experience less wear and tear. Minimizing wear over time and resulting in prolonged tool service life and reduced operational costs, non-contact components ensure exceptional durability in our linear motors.

♢ Efficient and Cost-effective: The frictionless motion of linear motors leads to greater efficiency, lower energy usage, and reduced operating costs. With higher speeds, superior precision, and lower vibration compared to conventional motors, they present a more efficient alternative in metal fabrication.

As CNC technology and automation become increasingly prevalent in manufacturing facilities, linear motors are gaining prominence due to their agility and versatility. While traditional methods relying on rotary motors and ballscrews still prevail, they need to achieve the speed and adaptability of linear motors. The swift movements and easy control over material flow offered by linear motors set a new production efficiency standard.

LUBI – Revolutionizing Metal Fabrication with Cutting-Edge Motion Control Components

LUBI's commitment to pioneering Motion Components technology is reshaping the landscape of metal fabrication. The company's dedication to innovation and precision enables manufacturers to optimize their metal fabrication processes, resulting in increased efficiency, reduced production times, and enhanced overall quality.

Linear motors are receiving significant attention in metal fabrication due to their swiftness and precision. LUBI is committed to cutting-edge Motion Components technology to ensure smoother, faster, and more efficient metal fabrication processes.

At Lubi, we focus on providing state-of-the-art Motion Components solutions to meet the unique needs of the metal fabrication industry. Our team of experts is dedicated to offering guidance and support to help enterprises achieve their production goals efficiently and effectively.

For a detailed understanding of our extensive Motion Components solutions, don’t hesitate to contact our experts.