Sit amet, consectetur adipiscing elit. Ut elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

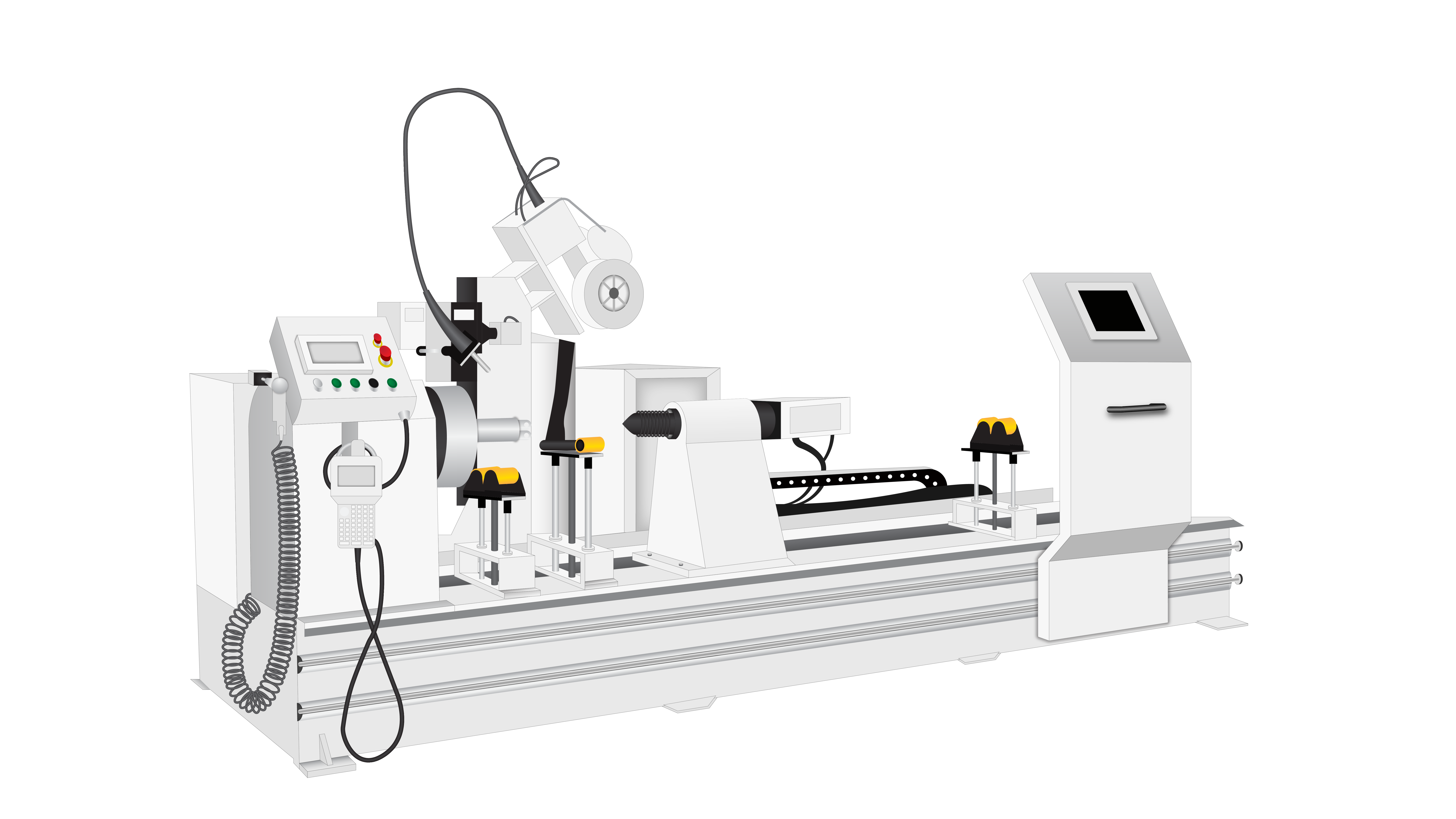

Project carried out by LUBI for welding application aims to weld Automobile vehicle parts like cylinder pot circular welding, Battery box line welding and many different components used in assembly line. The solution for multi axis machine offers MIG and TIG arc welding position the torch in same origins in every cycle with repeatable speed and arc gap ensure every fabrication is welded to the same high standard. High precision and torque servo motors optimized with Motion controller enables flexible profile welding operation assembling smaller components.

Automotive parts need the utmost consistency and precision when being made on the production line machines. Automotive manufacturers focus on strategic welding process that integrates automation technology for safer, faster and profitable production line and strive to have solution for flexible profile welding suitable to various automotive component parts.

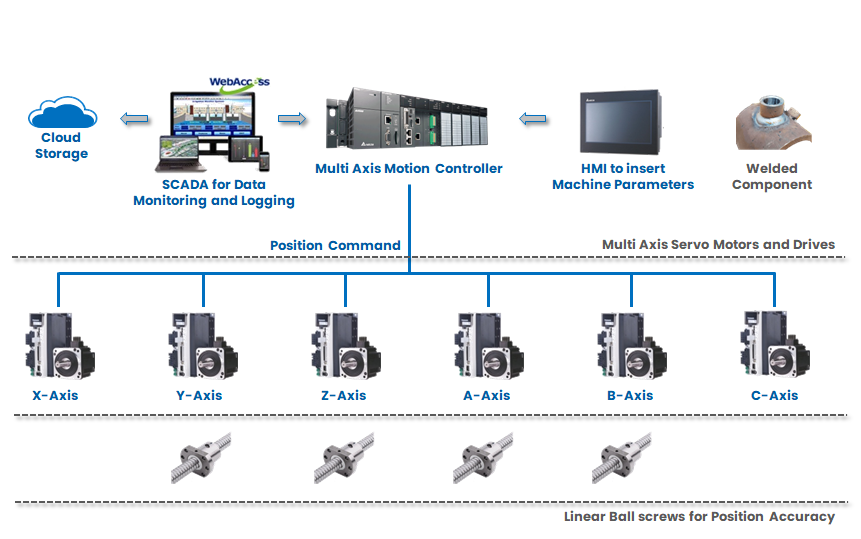

Welding automation typically uses robots, Linear motion guides or ball screws for accuracy while high precision AC servo motors mounted to achieve X,Y,Z coordinates in programming to increase the performance of production weld up to ±0.1mm interpolation repeatability.. Multi axis Motion controller and Programmable logic controller with modular design supports high frequency PTO to operate servo motors following specific path smoothly along with correction as needed for Torch. Welding is most complex manufacturing process that actuates Controller to operate Servo motors on fast Ethernet communication to transfer better dimensional data achieving high precision welding for ease of wiring and reduce electrical maintenance.

Computer based software makes operation inevitable for profile programming enabling manufacturers to insert multiple coordinates desirable to various automotive components. AC Servo motors carrying high payload capability enhance the operation to weld heavy car body panels precisely while ball screw and Gear box mechanism makes operation repeatable to meet high weld standards.

LUBI offers future proof solution to automotive manufacturer build their machines with flawless design connecting high precision linear ball screws and low backlash gear box for accurate axis position. It also provides 32bit & 64bit Motion control system for position accuracy & AC servo System which optimizes closed loop motion control system with safety interlocks. Customer can also employ LUBI’s IIoT software integrated for Cloud storage & Data monitoring of machine alerts, production data and online modifications for flexible program orientation.

Flexible program to weld varied automotive components

✔ Complex Profile of Interpolation : Linear,Circular,Helical & Conical, Spherical

✔ Axis Interpolation achieves accuracy up to ±0.1mm & 5mm/sec to 30mm/sec speed

✔ Various DXF format import option in Controller

✔ Multi Axis Motion control system for 64bit positions for multipoint weld

Precise Motion Products ensures smooth and consistent weld

✔ Precision ground ballscrews for high positioning accuracy and repeatability

✔ Servo grade planetary gearboxes offers low backlash of 6Arcmin

✔ Closed loop Servo Motors for faster movement upto 200mm/Sec

Solution helps safe, sustainable and cost optimized production

✔ Welding increase safety in workshop removing human element

✔ Solution enables to produce accurate, high-quality welds with fewer mistakes and less accidents

✔ Consistent weld without delay and within time constraints save production cost