Sit amet, consectetur adipiscing elit. Ut elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

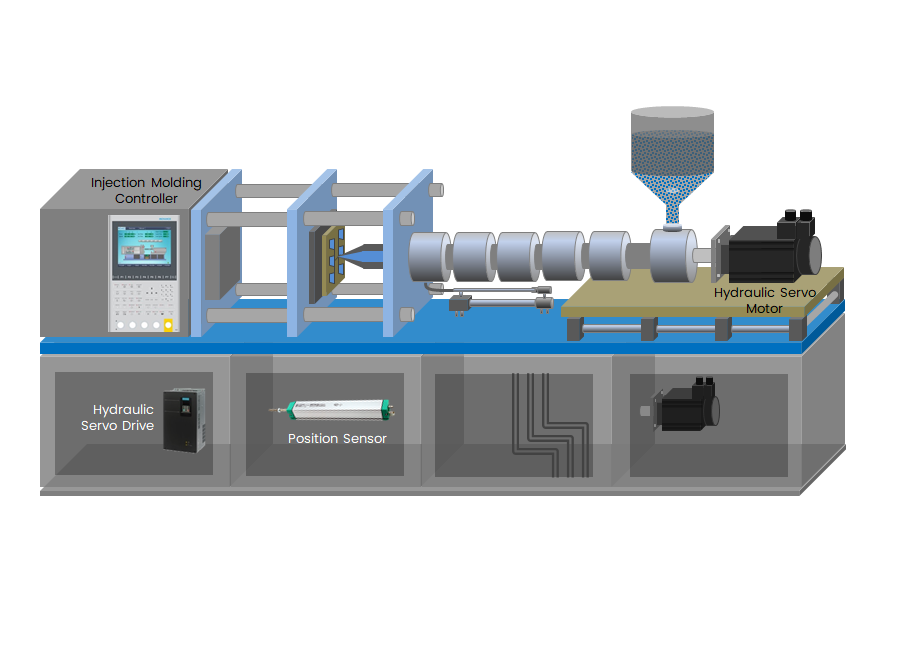

Injection molding is that it comprises production of many identical parts, which allows for part reliability and consistency in high volume production. Industry 4.0 supported rubber and Plastic industry to innovate all electric IM machine with servo drive operation for motion reducing less wear and tear of mechanical assembly parts. The automated injection equipment ensures the same amount of material get injected in mold each time along with many related variables.

The main working principle of Injection molding machine is the reciprocating screw rotates by means of a motor and its reciprocating motion is provided by the hydraulic system. The Plastic granules are to be poured into the hopper and they will be passed through the chamber due to the rotation of the screw.

Machine uses high pressure and heat in plastic injection molding to drive melted plastic into a heated mold, where it cools and takes on the required shape. The smoothness of the cooled product necessitates little extra processing. Before the final outcome it passes through several processes like Mold development, Clamping, Injection, cooling, ejection and final finishing process. Aim of the machine is to maintain pressure and temperature of melted material with reduced cycle time for high production ratio.

All these measures configured with incorporating precise pressure and temperature transmitters provided by LUBI to prevent newly molded parts becoming fragile and vulnerable from deforming with fluctuating pressure.

We offer Linear and angular position transducers to detect the position of mechanical parts in motion for die open and close. Real-time position detection makes it possible to reduce machine cycle times and to intercept points for actuation of other servomechanisms in the stroke.

Customer focus on more to have integrated product solution for their machines and LUBI caters efficient Injection Moulding controller including Energy saving system (ESS) with close loop FVC control of Pressure and Temperature Transmitters with precision accuracy of Position transducer for cost saving and efficient production performance.

Performance Package Delivering High Accurate Production

✔ Provides Controller and ESS as efficient and energy saving package

✔ Pressure and Temperature sensors make versatile operation in close loop

✔ Cost saving and Precision driven Performance

Versatile Hydraulic Motor Solution

✔ Closed Loop FVC Control

✔ Starting Torque of 180% at 0Hz in FVC Control

✔ Comprehensive Strip Diagnostic and Flexible IO Programming

Electric Melt Solution

✔ Direct Driven Melting System reduces Mechanical Transmission and Save Energy Consumption up to 10%

✔ High reliability and adaptability to environment