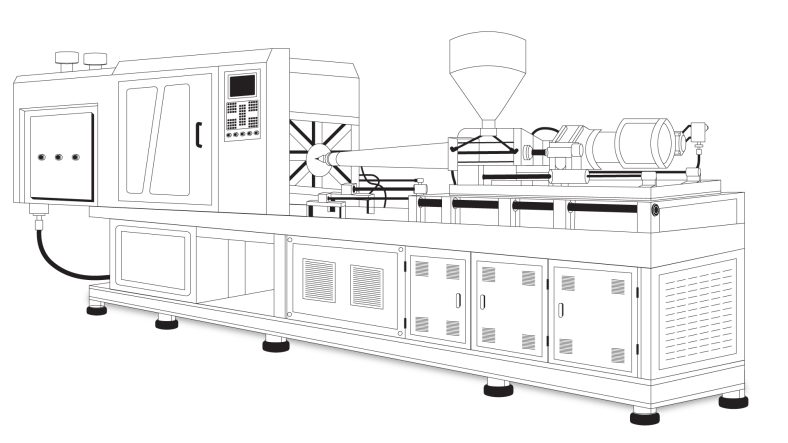

Injection Molding Machine

The Traditional Process of manufacturing plastic parts has been upgraded to Automatic injection molding machine to make production faster, reliable and safe in which labor is minimized and less skill is required. For mass production, automation of molding machines can justify their initial cost and at the same time the quality of work also enhanced. Using advance equipment and automation technology LUBI enables customer to upgrade their machines with compete production line automation through Injection molding controller with Hydraulic servo control and drive integrated solution for energy saving measures.