- Home

- All Partners

- CTB

- Servo Spindle Drive & Motor

- Servo Spindle Motor Z18 Series

Servo Spindle Motor Z18 Series

- Home

- All Partners

- CTB

- Servo Spindle Drive & Motor

- Servo Spindle Motor Z18 Series

Servo Spindle Motor Z18 Series

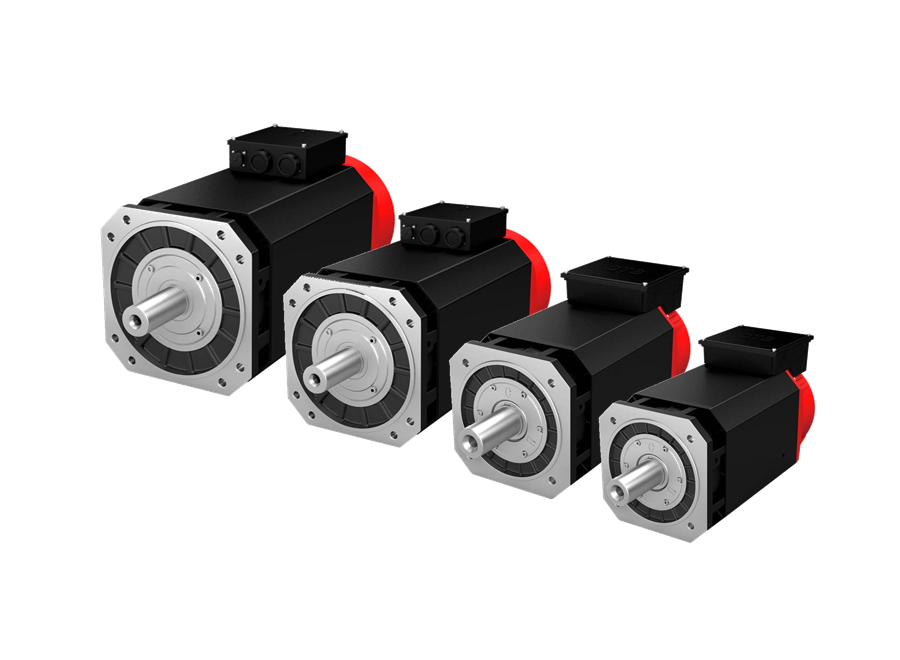

Servo Spindle Motor Z18 Series

Z18 series servo spindle motor, which is developed, designed and produced by CTB,is a new type of AC spindle induction servomotor with international advanced level

Z18 series servo spindle motor has a compact structure, superior function, good shape and high efficiency, widely used in variousfields of machinery manufacturing with very good cost performance

The design and production of Z18 series servo spindle meet is accord with relevant standards, such as ISO, IEC, GB, etc. Z18 series servo spindle motor can reach energy efficiency grade 2 of GBZ18613-2012 standard and IE3 of IEC60034-30 standard

● Compact Structure & Good Shape

● High efficiency & Low Noise

● Optimal energy-saving design with enclosed cooling air duct

● High torque cutting at low speed

● Constant power cutting with high speed

● Zero speed spindle lock

● Accurate stop control

● C-axis function

● Rigid tapping

Applications

-

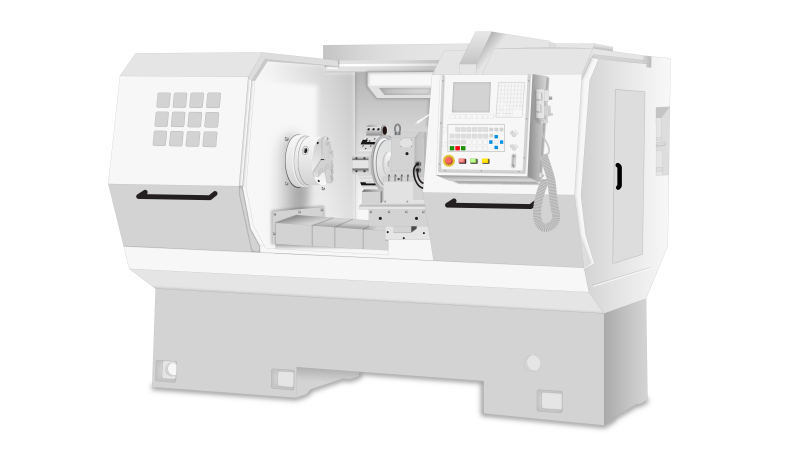

Lathe Machine Automation

Modern Technology makes future products using computer software, hardware and firmware in industry. Lathe machines are becoming more important in modernized industrialization and conventional Lathe machines are required to be retrofitted by advance semi-automatic control to get more accurate dimensions and irregular shapes. Developing and changing into semi-automatic need mechanical and electronics components to be replaced.Mehcanical side LUBI replaces Ball screws in place of Lead screws for better accuracy and removes some unnecessary components with Gear reducers. Electronic side it provides Spindle, AC Servo & Stepper motors driven by intelligent controller for efficient operation. While safety measure for human intervention is carried out by smart safety sensors.

-

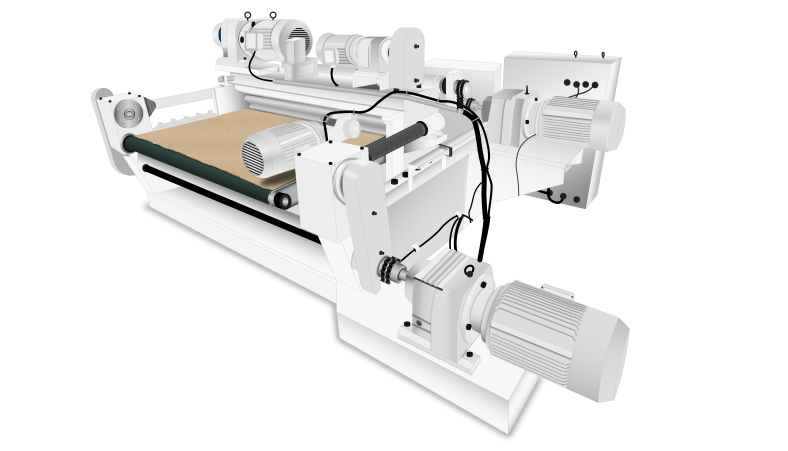

Wood Veneer Peeling Machine

Wood Veneer Peeling machine has been main equipment in Plywood production for splicing thin layer wooden sheets. Traditional machinery continues to find ways to meet the current environmental protection trends and to maximize the utilization of resources. Therefore, customer needs robust automation solution that offers excellent performance upgraded to servo spindle based operation for precision cutting carrying high load capacity with ensuring cost effective production. Comprehensive engineering carved by LUBI caters new generation automation products for feeder roller and cutter motor in veneer peeling equipment for accurate thickness of veneer enabling efficient production of high quality products.