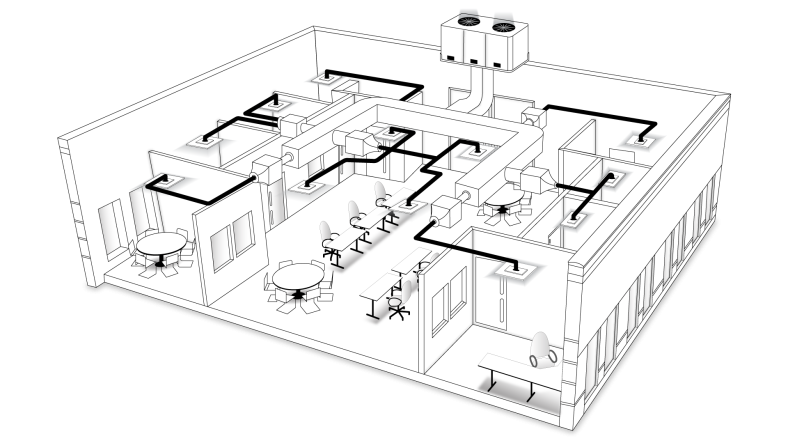

Heating,Ventilation and Conditioning

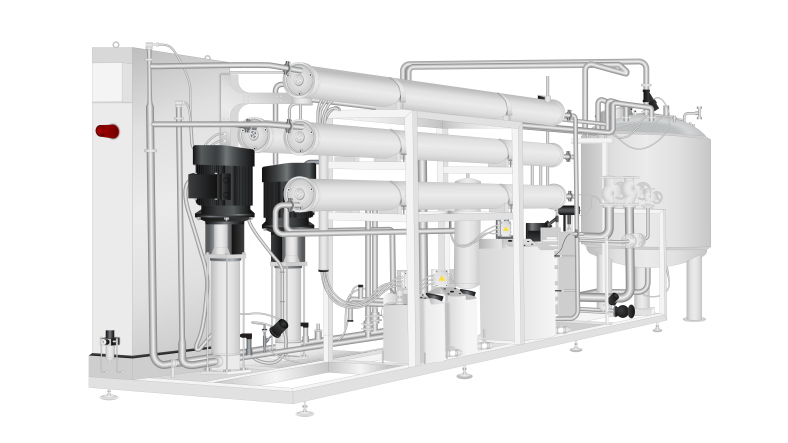

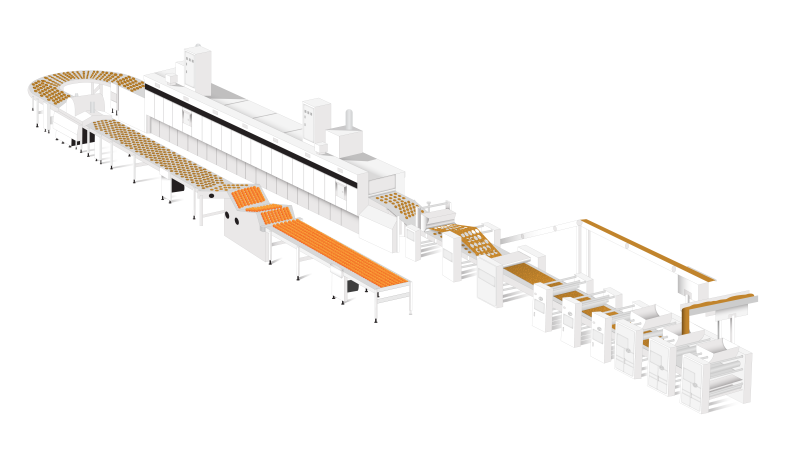

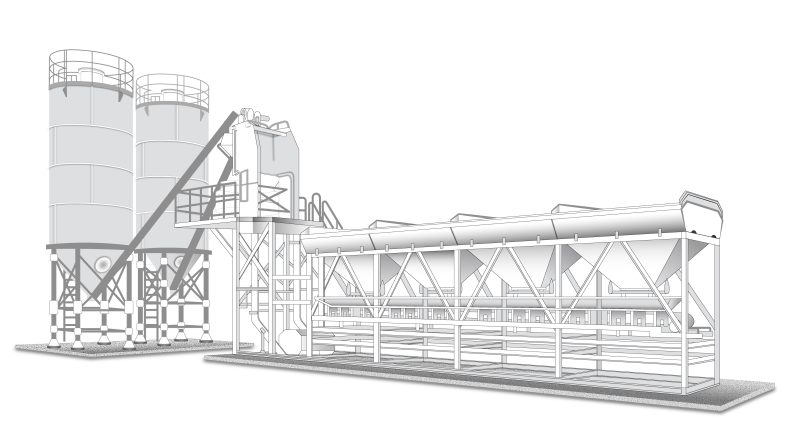

HVAC is the Technology of indoor and Vehicular environmental comfort. The aim of such system is to provide thermal comfort and acceptable indoor air quality, especially important to medium and Large scale buildings such as offices, Residential Towers, Hotels and Malls, while it also plays wide role in specific industry where HVAC system control must applied like Dairy Plants, Cold Storages and Power Generation Plants. The system maintains safe and healthy conditions of buildings by regulating Temperature and Humidity using fresh air from outdoors. LUBI caters control panel solution with sustainable product integration to enhance performance and IoT enabled cloud base data monitoring software to control the environment of the space incorporated.