- Home

- All Partners

- Panasonic

- AC Servo System

- MINAS A6

MINAS A6

- Home

- All Partners

- Panasonic

- AC Servo System

- MINAS A6

MINAS A6

MINAS A6

Panasonic A6 Series servo is more compact, faster, and more easy-to-use that meets the demands of the present age. Servo motors are high speed, high torque, and lightweight. Panasonic A6 series driver is a swifter, smarter, and easier to use. It has High speed response and high-precision positioning for quick and accurate movement. It has a new two degree of the freedom control system, Built filters, and adjusting functions. It has a 3.2 kHz frequency response to improve productivity.

Panasonic A6 series has a Battery-less Absolute Encoder motor available. It’s Maintenance-free - there is no need to perform a battery replacement. The battery-less absolute encoder is an innovative encoder requiring no hassle of inventory management or cost of battery replacement. It contributes to the construction of ecological and economical industrial machines and systems.

Panasonic A6 series motors protected by a highly dust-proof, oil-tight oil seal (with protection lip) have been added to the motor equipped with oil seals of conventional specifications. The oil seals of this type of motor are made of a material of higher heat resistance.

● Rated Torque: 0.16 Nm to 140.0 Nm

● 23-bit Absolute / Incremental Encoder Resolution

● Battery-less Absolute Encoder Motor available

● Position/ Internal Position/ Speed/ Torque & Full Close Control Modes

● 3.2 kHz Ultrafast Velocity Response frequency

● 8Mpps Exclusive Interface for Line driver Pulses

● Maximum 6500 RPM

● Maximum Torque Limit 350%

● RS-485/ RS-232 MODBUS-RTU communication

● Support 256 Internal Position through Digital Input & MODBUS

● Communication

● Quadrant projection suppression function

● Detachable Keypad

● Compact motor size

● Low cogging torque

● Advance PANATERM software for PC Interface

● Motor sizing software

● CE & UL & European safety standard compliance

● IP 67 (Except Connector & Motor Shaft)

Applications

-

Vertical Foam Filling & Sealing

Raised consumer demands in market makes OEMs imperative to upgrade their packaging machines for optimize packing process to achieve maximum machine speed with enhanced performance, premium quality packaging and at the same time keeping cost in control.LUBI’s packaging solution for VFFS machine with integrated products offers machine builders to compete in the market and meet various industry standards, reduces engineering efforts, improves machine performance and save development cost with reduced time to deliver product in market.

-

Rotary Corrugated Sheet Cutting Machine

Safety of goods matters a lot for products taking care of its quality and making them ideal for transporting. Packaging material must be durable and providing stability which can be helpful when products are shipped long distanced and handled by warehouse. Corrugated cardboard known as fiberboard is perfect solution widely used by Industry for supply and logistics due to its varied thickness and job of wicking moisture away from products. Automation enables corrugated sheet manufacturer produce cardboards of any shape and size with multiple sheet layers for optimal handling and distribution in industry supply and logistics. Making of Cardboard must be with optimized length and reduced wastage, LUBI offers motion PLC for precise cutting and provides high frequency drives to carry heavy load of cutter in corrugated sheet industry for rotary cutting solution.

-

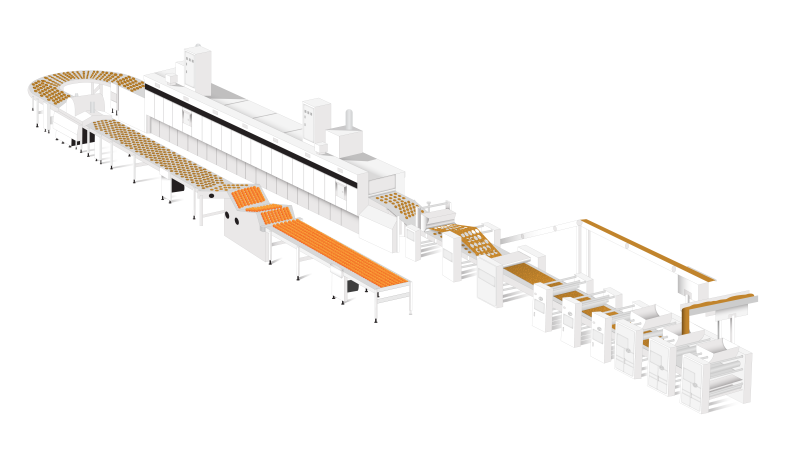

Biscuit Making Plant

The emerging biscuit market demands fully or partially automatic production line, especially in developing industry segment where traditional process of biscuit making is still high. Biscuit manufacturers automating production line prefers scalable performance of operation and flexible packaging solution adaptable to various pack size, format and material for seasonal promotion and to adjust consumer demand. Innovative solution of LUBI for biscuit making plant enables manufacturers customized product integration of various processes tailored for diverse demands of targeted customers in market and allows producers to reduce operator errors and downtime through repeatable and programmable set-ups.

-

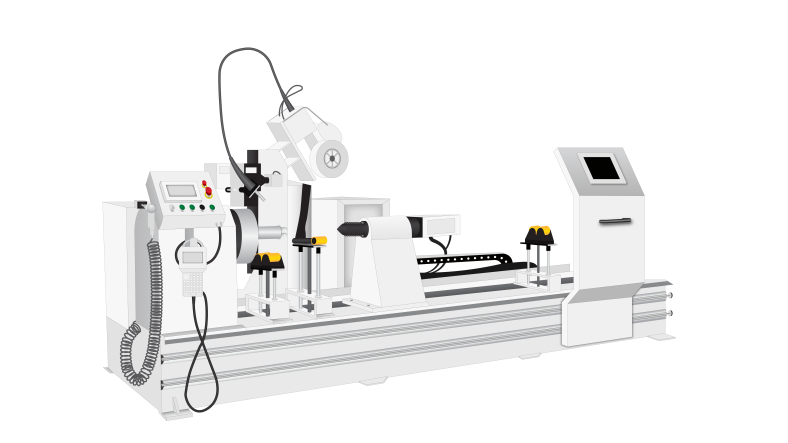

Welding Solution For Automotive Industry

The leading edge technology in welding application for automotive industry has become essential today making new combination of Auto body Parts. Innovative welding technique enables automotive manufacturer focus on welding process to joint lighter yet strong and fuel efficient vehicle parts employing lightweight materials. Welding solution of LUBI in automotive industry offers manufacturers flexible and sustainable welding development with the help of advance automation products and high precision mechanical parts for complex corrosive environments.

-

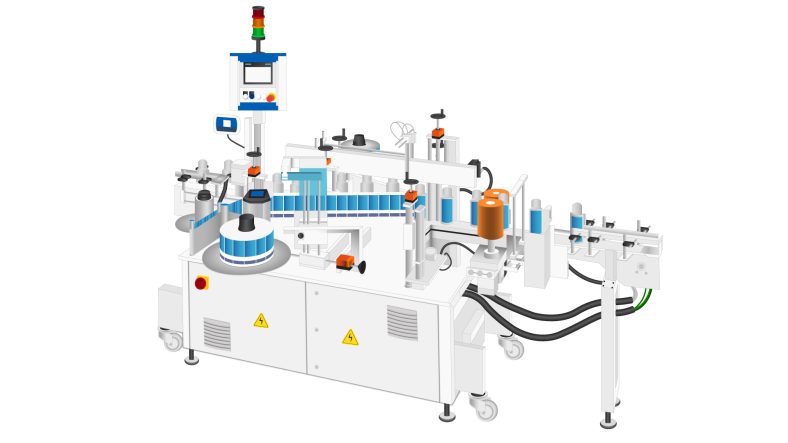

High Speed Bottle Labeling Machine

Being involved in the Production industry either it is Food, cosmetic or Pharmaceutical industry, certain procedure of labeling must be followed. Labeling is an important step because it identifies the product and conveys information of ingredient and other components making of it with price and manufacturing details. Hiring of employees for labeling of bottle would be costly & time consuming. LUBI enables customers in order to save time and reduce production cost by offering controller and sensing solution which makes labelling machine operates at high dispensing rate to label both sides of bottle considering time constraints. A High speed Label applicator machine can immensely influence your business rate and improve production efficiency.