- Home

- All Partners

- Advantech

- Industrial Networking Solution

- Unmanaged Ethernet Switches

Unmanaged Ethernet Switches

- Home

- All Partners

- Advantech

- Industrial Networking Solution

- Unmanaged Ethernet Switches

Unmanaged Ethernet Switches

Unmanaged Ethernet Switches

With no setup required, Advantech’s unmanaged Ethernet switches are truly plug-and-play and are designed for use in demanding industrial environments.

● Plug-and-Play

● Robust Communication Solutions

● High Versatile Switch Products

● 100 MBPS to GE Speed Support

● Single-mode Multimode fibre port support

● Wide temperature Range

● Flexible mounting option

● ATEX/C1D2/IECEx certification support

● AC-DC Power Supply Option

Port Range : 5 to 24 Port

Applications

-

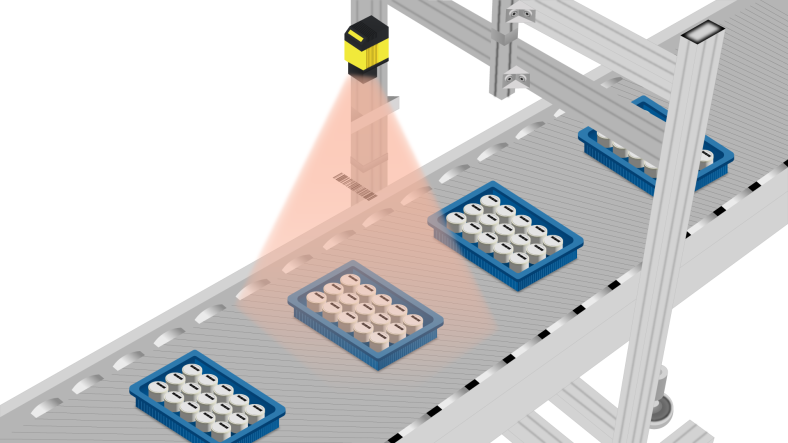

Image Based Barcode Scanning

Image based Barcode Readers are rapidly upgrading manual process and old traditional laser scanner in many of industries like Food and Beverages, Logistics and Pharmaceutical. The Series comes with fixed mounting type to solve complex, high throughput in logistics applications offers flexibility to manufactures think less about setup in their machine design. LUBI delivers image based barcode readers to read multiple challenging 1D and 2D codes in varied locations on production line, ideal for automotive and logistics component traceability.

-

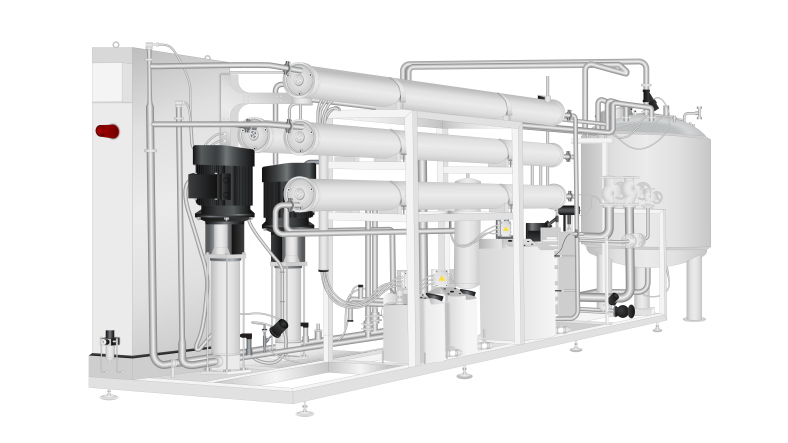

RO Water Distribution System

The water industry is one of the most remarkable industry undergoing many changes as demanding consistent approach and sustainable solution. Major Industry segment is involved in waste water processing, water purification with quality assurance and supply of drinking water in urban and rural area as well contributing reliable operation of water supply system.

LUBI discovers flexible and innovative solutions offering Industry 4.0 products of approved partners for the growth of water industry. Comprehensive product portfolio for digitalization and automation driving technologies offered by LUBI are highly adapted to fulfill requirements of customers.

-

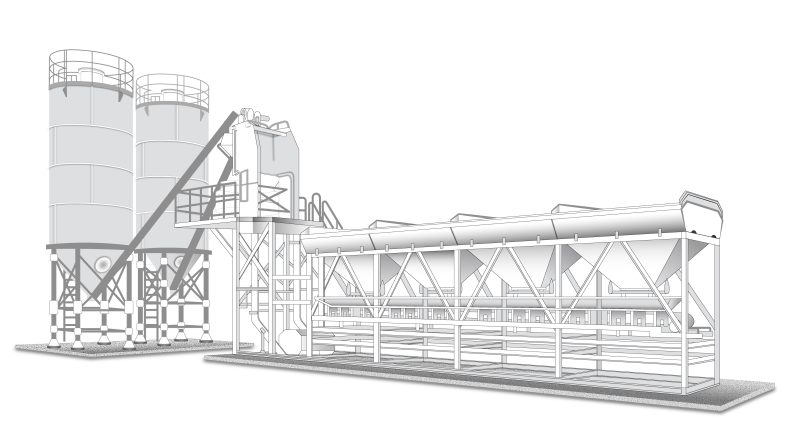

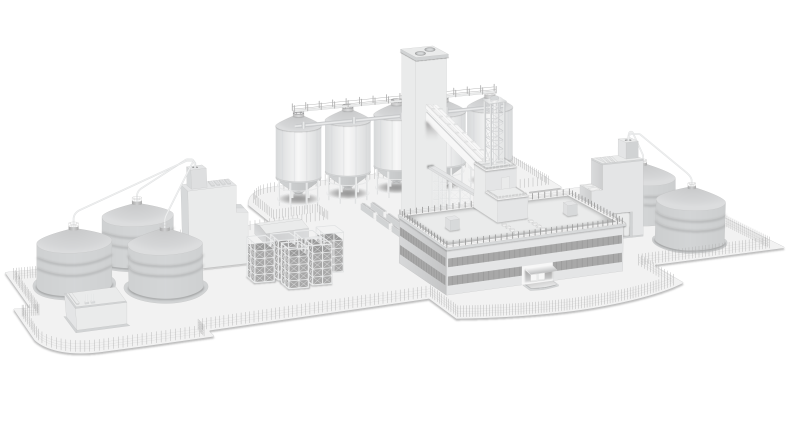

Concrete Batch Mixing Plant Application

Infrastructure Industry always strive to complete project within a time frame and has found its way to concrete batch mix Plants. The main purpose of using a concrete batching plant is to produce homogenous and uniform concrete consistently in batches one after the other in the same proportions. The most important function performed by this plant is that it coats the aggregates with cement. It becomes necessary that the concrete batching plant must be efficient and speedy in order to complete a construction project as soon as possible.

-

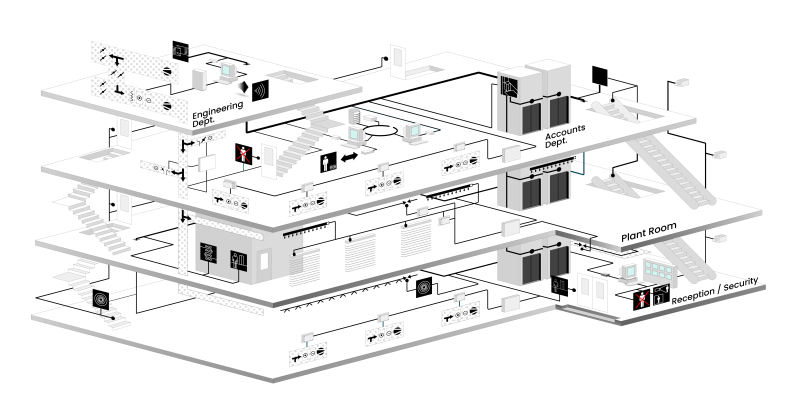

Energy Management System

Intrinsically in Home, Offices and Industries inefficient electrical equipment leads to energy wastage and create noise interference as well which reduces power quality. The key to cope up this challenge and increase efficiency is Energy Management System. LUBI carries the technology and solutions to mitigate the energy optimization issue which help to adapt changing electricity generation problems with enhanced energy efficiency and provide lower production cost & increased profit. LUBI offers integrated automation products for process control, energy measurement & cloud based IoT software systems designed with scalable architecture.

-

Pump Assembly Line Monitoring

Automated Water Pump and Motor assembly line enhances production with efficient use of measurement instruments and reduces error of Data essential to categorise pump performance. To make production process more efficient and user friendly, the perfect objective of manufacturing process involves accurate use of scaled instruments, fast data routing to storage and enhanced production enables to absorb the most out of industry 4.0 and adapt revolutionary technologies. LUBI offers persistent Data monitoring of Water Pump assembly line manufacturing for analytics and storage of big Data, so that you can match the needs of your unified products and environments.

-

Intelligent Process Control System for Fermentor Industry

Fermentation is complex process to monitor and control, particularly when traditional systems used to consummate the purpose. It is often impossible to directly measure the state of the control process online for fermentation. To overcome such deficiency in typical fermentation process, it becomes imperative to deploy automation control system for appropriate decision making, missed actions as a result of human scan rates, lower yields, lower production rates and increased downstream process variability. Automation technology and engineering expertise of LUBI enables precise control and monitoring over the industrial fermentation to produce bulk and fine chemicals in F&B and pharmaceutical industries.