DOP-100 Series HMI is designed using latest Cortex-A8 high speed processor and 65,536 color LCD display panel with high brightness and contrast. The DOP-100 Series is having various communication ports and Ethernet HMI support NTP (Network Time Protocol), FTP (File Transfer Protocol), E-Mail, VNC (Virtual Network Computing) and Remote Monitoring functions which is suited to meet customer requirements for cloud applications / smart manufacturing.

● Embedded Linux System – Open system for flexible and stable program development

● LUA Language — Simple and easy structural programming language to meet various demands

● Diagnostics Function — Collects and solves issues remotely

● Supports GIF Graphic Elements — Easy setting to play vivid GIF elements

● Supports PDF and TXT Reader — PDF and TXT files supported

● Multilingual Input –16 different languages input for easy operation

● Supports Different Printer Drivers — Dot Matrix, LaserJet, etc.

● Power Isolation — Protects the HMI from accidental surge interference

● Communication Isolation — COM and Ethernet ports with built-in isolation circuits enhance communication stability

● FTP/eMail Supported — Simple data transmission and real-time status report (Ethernet HMI)

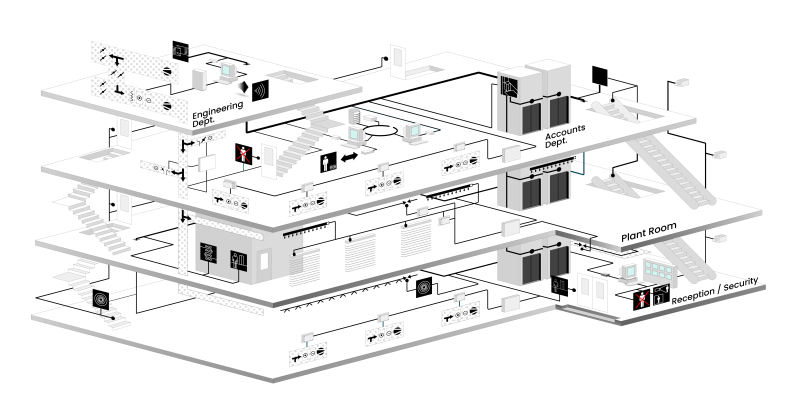

● VNC Remote Monitoring — Remote control with mobile devices (Ethernet HMI)

● Multimedia Functions — Captures image with an external camera or replays important recordings (Multimedia Type Model)

● User Management — Supports 7 user levels and 20 accounts in each level with a complex password facility.

● Operational Log — Every activity of users can be logged in a non-editable format

SIZE

4.3″ , 7.0″ 10.0″ 12″ & 15″